Uma uqala iphrojekthi ethokozisayo - kungakhathaliseki ukuthi yakha umshini we-CNC wedeskithophu enembile noma wamaphutha noma ingalo yerobhothi ehamba kahle - ukukhetha izingxenye zamandla ezibalulekile ngokuvamile kuwukhiye wempumelelo. Phakathi kwezingxenye zokubulala eziningi, ama-micro stepper motors abe yinketho ekhethwayo yabenzi, onjiniyela, nabakhiqizi ngenxa yokulawula kwawo okuvulekile okuvulekile, ukugcinwa kwetorque okuhle kakhulu, kanye nezindleko eziphansi uma kuqhathaniswa.

Kodwa-ke, lapho ubhekene namamodeli ahlukahlukene kanye nemingcele eyinkimbinkimbi, ungayikhetha kanjani i-micro stepper motor efanelekile kakhulu yerobhothi yakho noma umshini we-CNC? Ukukhetha inketho engalungile kungase kubangele ukunemba okungaphansi kwezinga, amandla anganele, noma ukwehluleka kwephrojekthi. Lo mhlahlandlela uzosebenza njengemanuwali yakho yokugcina yokukhetha, ikuthathe isinyathelo ngesinyathelo ukucacisa zonke izici ezibalulekile futhi wenze izinqumo ezihlakaniphile.

Isinyathelo 1: Qonda izidingo ezibalulekile - umehluko oyisisekelo phakathi kwamarobhothi ne-CNC

Ngaphambi kokuhlola noma yimaphi amapharamitha, kufanele ucacise izidingo ezibalulekile zesimo sohlelo lwakho lokusebenza lwenjini.

Amaphrojekthi erobhothi (njengezingalo zerobhothi, amarobhothi eselula):

Izidingo ezibalulekile: impendulo eguqukayo, isisindo, usayizi, nokusebenza kahle. Amalunga amarobhothi adinga ukuma okuvamisile kokuqala, isivinini esishintshashintshayo, noshintsho lwendlela, futhi isisindo semoto sithinta ngqo umthwalo uwonke kanye nokusetshenziswa kwamandla.

Izinkomba ezibalulekile: Naka kakhulu ijika lejubane letorque (ikakhulukazi i-torque emaphakathi nesivinini esikhulu) kanye nesilinganiso samandla nesisindo.

Amathuluzi omshini we-CNC (njengemishini yokuqopha ye-axis engu-3, imishini yokusika i-laser):

Izidingo ezibalulekile: ukusunduza, ukushelela, ukugcina i-torque, nokunemba. Amathuluzi omshini we-CNC adinga ukunqoba ukumelana okukhulu ngesikhathi sokusika noma ukuqoshwa, ukugcina ukunyakaza okushelelayo ukugwema ukudlidliza, nokuma ngokunembile.

Izinkomba ezibalulekile: Naka kakhulu ukugcina i-torque ngesivinini esiphansi, ukulungiswa kwezinyathelo ezincane ukunciphisa ukudlidliza, nokuqina kwemoto.

Ukuqonda lo mehluko oyisisekelo kuyisisekelo sazo zonke izinqumo zokukhetha ezilandelayo.

Isinyathelo sesi-2: Ukuhunyushwa Kwamapharamitha Abalulekile Ezinhlanu zeMicro stepper Motors

Nazi izinhlaka ezinhlanu ezibalulekile okufanele uzinake kubhukwana ledatha.

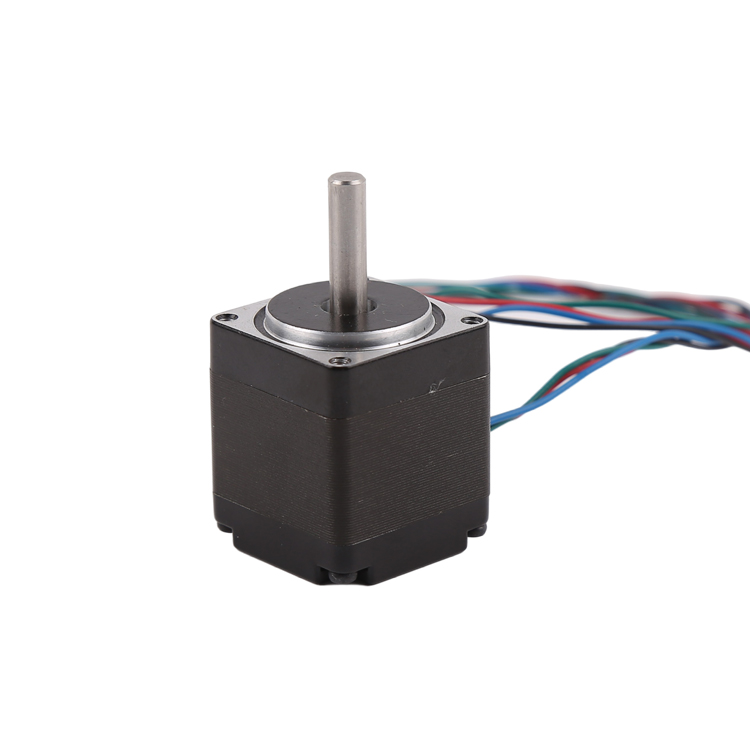

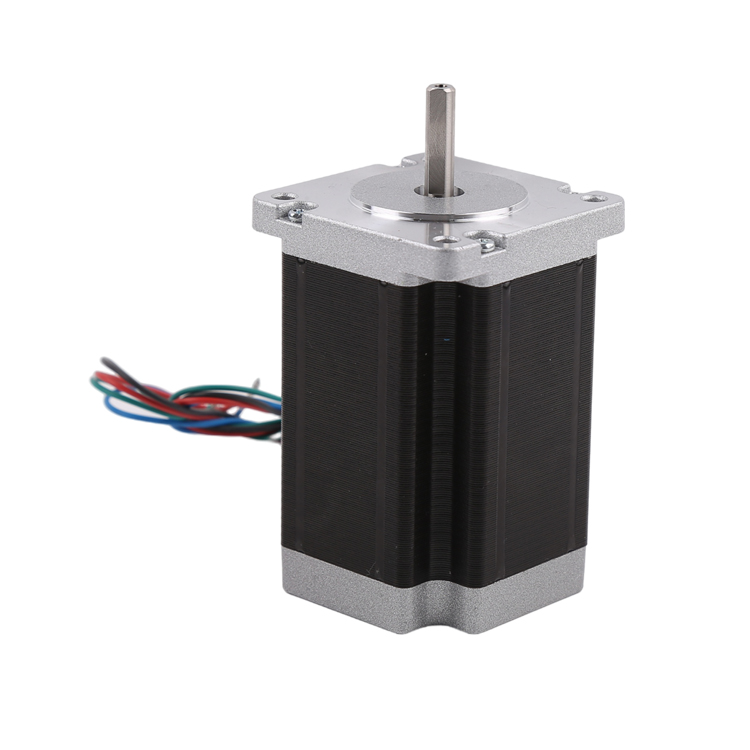

1. Usayizi kanye ne-torque - itshe legumbi lamandla

Usayizi (inombolo yesisekelo somshini): ngokuvamile kuvezwa ngamamilimitha (njenge-NEMA 11, 17, 23). Izinga le-NEMA lichaza ubukhulu bokufakwa kwamamotho, hhayi ukusebenza kwawo. I-NEMA 17 ingusayizi odume kakhulu wamarobhothi edeskithophu kanye ne-CNC, efinyelela ibhalansi enhle phakathi kosayizi netorque. I-NEMA 11/14 encane ifanele amajoyini amarobhothi okulayisha ukukhanya; I-NEMA 23 enkulu ifanele amathuluzi omshini we-CNC amakhulu.

Gcina i-torque: Iyunithi ingu-N · cm noma i-Oz · in. Lena itorque ephezulu engakhiqizwa injini uma inikwe amandla kodwa ingazungezi. Lesi yinkomba ebaluleke kakhulu yokukala amandla emoto. Ngamathuluzi omshini we-CNC, udinga i-torque yokubamba eyanele ukumelana namandla okusika; Kumarobhothi, kuyadingeka ukubala i-torque ephezulu edingekayo kumalungu.

Indlela yokulinganisa i-torque edingekayo?

Kumathuluzi omshini we-CNC, umthetho oqinile wesithupha ukuthi itorque enganikeza okungenani i-20-30N (cishe amakhilogremu angu-2-3) iyadingeka i-axial thrust. Lokhu kudinga ukuguqulwa ngokuhola nokusebenza kahle kwesikulufu. Kumarobhothi, izibalo eziguqukayo eziyinkimbinkimbi ziyadingeka ngokusekelwe kubude bengalo, isisindo somthwalo, kanye nokusheshisa. Qinisekisa ukuthi ushiya i-torque ye-torque engu-30% -50% ukuze ubhekane nezici ezingaqinisekile ezifana nokungqubuzana kanye ne-inertia.

2.I-angle yesinyathelo nokunemba - umphefumulo wesinyathelo

I-engeli yesinyathelo: njenge-1.8 ° noma 0.9 °. Injini engu-1.8 ° ijikeleza kanye ezinyathelweni ezingu-200, kuyilapho injini engu-0.9 ° idinga izinyathelo ezingu-400. Uma i-engeli yesinyathelo ibancane, iphakamisa ukunemba kwemvelo kwenjini. Injini engu-0.9 ° ivamise ukuba bushelelezi uma isebenza ngesivinini esiphansi.

3. Okwamanje kanye Nogesi - Ukufanisa Abashayeli

Isigaba samanje: Iyunithi yi-Ampere (A). Lona umkhawulo wamanje okaliwe ongakwazi ukumelana nesigaba ngasinye senjini. Le parameter inquma ngokuqondile ukuthi iyiphi idrayivu okufanele uyikhethe. Amandla okukhipha amanje omshayeli kufanele ahambisane nenjini.

I-Voltage: Ama-motor ngokuvamile akalwa ngama-voltage alinganisiwe, kodwa i-voltage yangempela yokusebenza ingaba phezulu kakhulu kunalokhu (inqunywa umshayeli). I-voltage ephezulu isiza ukuthuthukisa ukusebenza kwe-motor ngesivinini esikhulu.

4. I-inductance kanye nokusebenza kwesivinini esikhulu - izici ezibalulekile ezinganakwa kalula

I-inductance iyisici esibalulekile esithinta i-torque enesivinini esikhulu semoto. Ama-motor inductance aphansi angasungula okwamanje ngokushesha, okuholela ekusebenzeni okungcono ngesivinini esikhulu. Uma amalunga erobhothi lakho adinga ukuphenduka ngokushesha, noma uma umshini wakho we-CNC ufuna ukukhulisa izinga lokuphakelayo, kufanele ubeke kuqala ukukhetha amamodeli ane-inductance ephansi.

5. Uhlobo lwe-shaft kanye nendlela yomugqa ophumayo - imininingwane yokuxhuma ngomshini

Izinhlobo ze-shaft: i-optical axis, shaft eyodwa eyisicaba, i-double shaft flat, i-gear shaft. Ukunquma uhlobo lwe-D (i-flat shaft eyodwa) kuvame kakhulu futhi kungavimbela ngempumelelo ukuhlangana ekusheleleni.

Indlela ephumayo: ephumayo ngqo noma i-plug-in. Indlela ye-plug-in (njenge-4-pin noma i-6-pin head yendiza) ilungele ukufakwa nokugcinwa, futhi iyisinqumo sochwepheshe.

Isinyathelo sesi-3: Uzakwethu obalulekile - ungamkhetha kanjani umshayeli we-stepper motor

I-motor ngokwayo ayikwazi ukusebenza futhi kufanele ihlanganiswe nomshayeli we-stepper motor. Izinga lomshayeli linquma ngokuqondile ukusebenza kokugcina kwesistimu.

I-Microstep: Hlukanisa isinyathelo sonke kuzinyathelo ezincane (ezifana ne-16, 32, 256 microsteps). Umsebenzi oyinhloko wokunyathela okuncane ukwenza ukunyakaza kwemoto kube bushelelezi ngokwedlulele, kunciphisa kakhulu ukudlidliza nomsindo, okubalulekile kwikhwalithi engaphezulu yamathuluzi omshini we-CNC.

Ukulawula kwamanje: Abashayeli abahle kakhulu banomsebenzi wamanje wesigamu ozenzakalelayo. Yehlisa ukusebenza kwamanje ngokuzenzakalelayo lapho injini imile, yehlisa ukukhiqizwa kokushisa nokusetshenziswa kwamandla.

Ama-chips/amamojula omshayeli ajwayelekile:

Isigaba sokuqala: I-A4988- Izindleko eziphansi, ezifanele amaphrojekthi amarobhothi alula.

Ukukhetha Okujwayelekile: I-TMC2208/TMC2209- Isekela ukushayela buthule (imodi ye-StealthShop), isebenza ngokuthula ngokwedlulele, iyisinqumo esihle kakhulu samathuluzi omshini we-CNC, futhi inikeza imisebenzi yokulawula ethuthuke kakhulu.

Ukusebenza okuphezulu: I-DRV8825/TB6600- inikeza ukwesekwa okuphezulu kwamanje kanye ne-voltage, ifanele izinhlelo zokusebenza ezidinga i-torque enkulu.

Khumbula: umshayeli omuhle angakwazi ukwandisa amandla emoto.

Isinyathelo sesi-4: Inqubo Yokukhetha Esebenzayo kanye Nemibono Engalungile Evamile

Izinyathelo ezine zokukhetha indlela:

Chaza umthwalo: Chaza ngokucacile isisindo esiphezulu, ukusheshisa okudingekayo, nesivinini umshini wakho odinga ukuhamba ngaso.

Bala itorque: Sebenzisa umshini wokubala wetorque eku-inthanethi noma ifomula yomshini ukuze ulinganisele itorque edingekayo.

Ukukhetha kokuqala kwama-motors: Khetha amamodeli amakhandidethi angu-2-3 ngokusekelwe ku-torque nezimfuneko zikasayizi, bese uqhathanisa amajika ejubane letorque.

Fanisa umshayeli: Khetha imojuli yomshayeli efanelekile kanye nokunikezwa kwamandla okusekelwe kumthamo wesigaba senjini kanye nemisebenzi edingekayo (njengesimungulu, ukuhlukaniswa okuphezulu).

Imibono Eyiphutha Evamile (Ukugwema Imigodi):

Umbono oyiphutha 1: I-torque enkulu, iba ngcono. I-torque eyeqile isho amamotho amakhulu, isisindo esisindayo, kanye nokusetshenziswa kwamandla okuphezulu, okulimaza kakhulu amalunga amarobhothi.

Umbono oyiphutha 2:Gxila kuphela ekugcineni i-torque futhi uzibe i-torque enesivinini esikhulu. I-motor ine-torque ephezulu ngesivinini esiphansi, kodwa njengoba isivinini sanda, i-torque izokwehla. Qiniseka ukuthi uhlola ishadi lejika lejubane le-torque.

Umbono oyiphutha 3: Ukunikezwa kwamandla anganele. Ukunikezwa kwamandla kungumthombo wamandla wesistimu. Ukunikezwa kwamandla okubuthakathaka akukwazi ukushayela injini ukuthi isebenze ngamandla ayo aphelele. I-voltage yokuphakela amandla kufanele okungenani ibe indawo emaphakathi ye-voltage elinganiselwe yomshayeli, futhi umthamo wamanje kufanele ube mkhulu kuno-60% wesamba sayo yonke imisinga yesigaba sezimoto.

Isinyathelo sesi-5: Ukucatshangelwa Okuthuthukile - Kunini Lapho Sidinga Ukucabangela Amasistimu Avaliwe Okulutha?

Ama-motors endabuko e-stepper alawulwa yi-open-loop, futhi uma umthwalo umkhulu kakhulu futhi ubangela ukuthi injini "ilahlekelwe isinyathelo", isilawuli asikwazi ukuqaphela. Leli iphutha elibulalayo lezinhlelo zokusebenza ezidinga ukwethembeka okungu-100%, njengokusebenza kwe-CNC yebanga lezentengiso.

I-closed-loop stepper motor ihlanganisa isifaki khodi ekugcineni kwemoto, engaqapha indawo ngesikhathi sangempela futhi ilungise amaphutha. Ihlanganisa izinzuzo ze-torque ephezulu ye-stepper motors nokuthembeka kwama-servo motors. Uma iphrojekthi yakho:

Ayikho ingozi yokuchezuka evunyelwe.

Kudingekile ukusebenzisa ngokugcwele ukusebenza okuphezulu kwemoto (i-loop evaliwe ingahlinzeka ngesivinini esiphezulu).

Isetshenziselwa imikhiqizo yokuhweba.

Ngakho-ke, ukutshala imali ohlelweni lwe-stepper oluvaliwe kuyafaneleka.

Isiphetho

Ukukhetha i-micro stepper motor efanelekile yerobhothi lakho noma umshini we-CNC wubunjiniyela besistimu obudinga ukucatshangelwa okuphelele kwezakhi zomshini, zikagesi, nezokulawula. Ayikho injini 'engcono kakhulu', kuphela injini 'efaneleka kakhulu'.

Ukufingqa amaphuzu awumongo, kusukela kusimo sohlelo lokusebenza, amarobhothi abeka phambili ukusebenza okuguquguqukayo nesisindo, kuyilapho amathuluzi omshini we-CNC ebeka phambili itorque emile nokuzinza. Bamba ngokuqinile kumapharamitha angukhiye we-torque, wamanje, kanye ne-inductance, futhi uyihlomise ngomshayeli osezingeni eliphezulu kanye nogesi owanele. Ngokuqondiswa kulesi sihloko, ngithemba ukuthi ungenza ngokuzethemba ukukhetha okuphelele kwephrojekthi yakho elandelayo enhle, uqinisekise ukuthi okudaliwe kusebenza ngokunembile, ngamandla, nangokwethembeka.

Isikhathi sokuthumela: Sep-25-2025