● Indima yokugingqa ama-bearingsizinjini

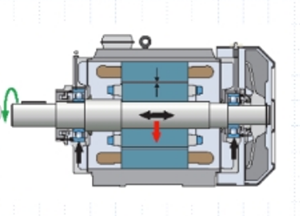

1, Sekela i-rotor.

2, Ukuma kwe-Rotor.

I-3, ukuqinisekisa ukuthi ubukhulu begebe lomoya, umfaniswano kusuka ku-shaft kuya esihlalweni ukuze udlulise umthwalo ukuvikela imoto kusukela ngesivinini esiphansi ukuya ekusebenzeni kwejubane eliphezulu.

4, ukunciphisa ukungqubuzana, ukunciphisa ukulahlekelwa.

Okudingeka kuqondwe ngokucacile ukuthi ama-bearings ku-motor awawuthwali umthwalo we-torque we-motor, ngakho-ke lokho okuvame ukubizwa ngokuthi isimo sokungalayishwa kwemoto kunomphumela omncane kuma-bearings.

● Ukungqubuzana

1, kanye nokuqina kwendawo yokuxhumana, ubulukhuni, nezimo zokugcoba - i-coefficient of friction.

2, ukungqubuzana okumile > ukungqubuzana kokuslayida > ukungqubuzana okuqengqelekayo.

3, i-coefficient yokungqubuzana ngokuslayidayo 0.1-0.2.

4, i-coefficient ye-rolling friction 0.001-0.002.

I-5, i-fluid dynamics friction - ama-bearings angenalutho.

Amabhereli anciphisa ukungqubuzana ngomshini futhi ukuthambisa kunciphisa ukungqubuzana ngamakhemikhali. Ngakho-ke, kuyadingeka ukuqonda ukungqubuzana ngaphambi kokuqonda ama-bearings.

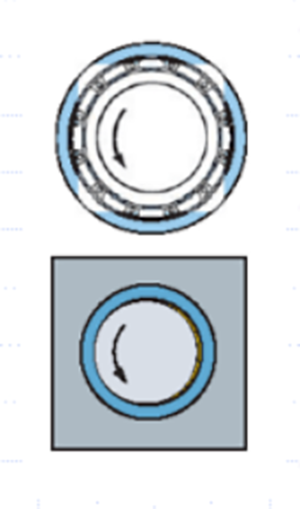

● Ama-Rolling and Plain Bearings

Ama-rolling bearings

1, I-motor ingafakwa ngokuvundlile noma mpo.

2. Angaqhutshwa ngesivinini esibanzi.

I-Slide Bearing

1, Ukubekwa kwenjini kudinga ukuklanywa kusengaphambili.

2, Ingasetshenziswa kuphela ngaphakathi kwebanga lejubane eliklanyelwe ukusebenza.

I-3, i-torque enkulu yokuqala, ayikwazi ukugijima ngesivinini esiphansi.

Ama-Rolling bearings nama-plain bearings ama-motor, ngaphezu kwemodi ehlukene yokungqubuzana, kukhona futhi umehluko ekusetshenzisweni.

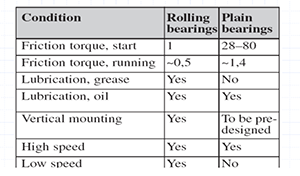

● Ukuqhathaniswa kwama-bearings aginqikayo nama-plain bearings

Umehluko omkhulu phakathi kwama-rolling bearings nama-plain bearings umehluko wokungqubuzana. Umehluko wokungqubuzana uletha umehluko ezimeni zohlelo lokusebenza. Ngakho-ke, kuyadingeka ukukhetha uhlobo lokuzala ngokuya ngemibandela yesicelo.

● Ama-bearings asetshenziswa kakhulu kumamotho wezimboni

I-1, ama-deep groove ball bearings DGBB.

2, Cylindrical Roller Bearing CRB.

3, i-CARB.

4, ama-insulated bearings ISOCOAT.

5, ama-Ceramic bearings.

6, I-Encoder Bearing.

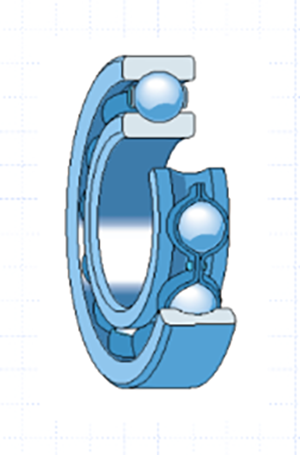

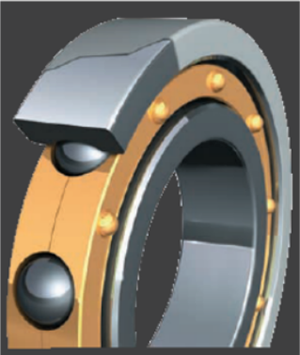

● Izici eziyinhloko zama-deep groove ball bearings

I-1,Umthamo omuhle kakhulu wokuthwala i-axial kanye ne-radial load ikwenza kube ukukhetha kokuqala kumamotho amancane naphakathi nendawo.

2, Ukulayisha kwangaphambili kungasetshenziswa yi-wave spring ukwenza injini isebenze ngokuthula nangokuthembekile.

3, izindlela ezahlukene zokuvala ukuze uzivumelanise nezidingo ezahlukene.

4, Ukushisa okubanzi kwamafutha kungasetshenziswa ukugijima ebangeni lokushisa elibanzi.

Ama-deep groove ball bearings wuhlobo olujwayeleke kakhulu lwama-bearings kumamotho kagesi, okubalelwa ngaphezu kwama-70% wawo wonke ukusetshenziswa kwezimoto zezimboni.

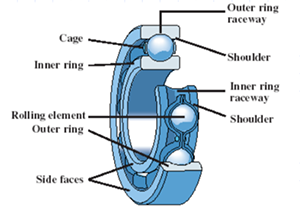

● Ukwakhiwa kwama-deep groove ball bearings

1, indandatho yangaphandle

2, indandatho yangaphakathi

3. Ikheji

4. Umzimba ogoqayo

5. Ikhava yothuli (ikhava yokuvala)

Ukuqonda izingxenye zamabheringi kusiza ukuvezwa konjiniyela konjiniyela.

●Ikheji lokuthwala

Ikheji yensimbi enesitembu: eqinile, imelana nezinga lokushisa eliphezulu.

Ikheji le-B Nylon: Ijubane eliphezulu lokugijima, umsindo ophansi, izinga lokushisa eligijima lifika ku-120 degrees.

izinga lokushisa kufika ku-120 degrees Celsius.

C Ikheji yethusi eyenziwe ngomshini: Iqinile, ingasetshenziswa endaweni yokudlidliza.

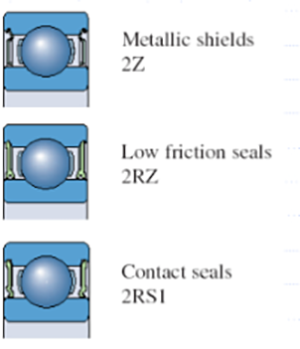

●Ukuthwala izimpawu

1, 27 - Isilinganiso sesivinini esifanayo njengama-bearings avulekile, umphumela wokuvala omaphakathi.

2, 2RZ - Umphumela omuhle wokuvala onesilinganiso sesivinini esifanayo namabheringi avuliwe.

3, 2RS1(H) -Umphumela wokuvala ongcono kakhulu, ukulinganisa isivinini esiphansi kunezibili zokuqala.

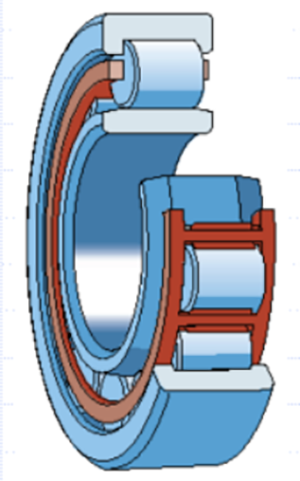

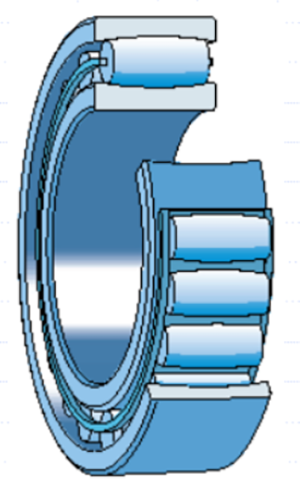

● Ama-roller bearings angama-cylindrical

1, babe nomthamo ongcono wokuthwala umthwalo kunama-deep groove ball bearings.

I-2, Ilungele kakhulu ukuphela kwe-belt drive yama-motor aphakathi nendawo namakhulu.

I-3, imiklamo ehlukahlukene ingasetshenziswa njengama-bearings angatholi indawo noma ama-bearings okuthola.

4, Amaphutha amakhulu okukhweza awavunyelwe.

Ama-Cylindrical rollers analezi zici, okuholela ekukhethweni kohlobo ngokusho kwalezi zici. Ukukhetha okuqondile kudinga ukucabangela umthamo womthwalo, umthamo wesivinini, ukulinganiswa kwempilo nezinye izici.

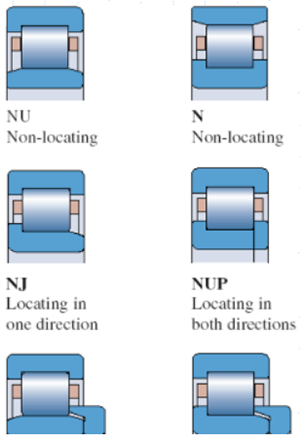

● Amabhodi ama-Cylindrical roller kumiklamo eminingi ehlukene

1, uhlobo lwe-NU - ama-bearings angatholi indawo anendandatho yangaphandle enorimu.

2, uhlobo lwe-N - indandatho yangaphakathi inomkhawulo wegiya, ama-bearings angatholi indawo.

3, N] uhlobo - iringi yangaphandle inonqenqema lwegiya iringi yangaphakathi inomphetho wegiya ohlangothini olulodwa, ukuma kwendlela eyodwa.

4, NUP - kuno-N] thayipha ngaphezu konqenqema olunyakazayo, ukuma kwezindlela ezimbili.

Izinhlobo ezihlukene zamabhodlela angama-cylindrical roller empeleni zinezici ezihlukile. Ngakho kukhona futhi izimo zohlelo lokusebenza ezahlukene. Isibonelo, i-N kanye ne-NU, kokunye ukusetshenziswa kwenqubo, kwezinye izici ezithwala i-lubrication, kunomehluko.

●Ama-CARB bearings

1, ingasetshenziswa esimweni lapho kunokungalungi kahle okukhulu phakathi kweshaft kanye nomugqa ophakathi nendawo wokuthwala ((kungaba ukuziqondanisa ngokwakho).

I-2, Bangakwazi ukufaka esikhundleni ama-cylindrical roller bearings njengama-bearings angatholakali kumamotho wezimboni.

3, Umbuthano ogcwele wangaphakathi nangaphandle ungasetshenziswa ngokulingana koguquko.

●INSOCOAT

1, Ithuthukiswe kusuka kuma-plain bearings.

2, Kukhona ungqimba oluvikelayo lwe-aluminium oxide kanye ne-resin kwindandatho yangaphakathi noma yangaphandle ukuvikela i-shaft current ukuthi ingalimazi ukuthwala.

3, Kufanele ibekwe ekugcineni okungashayeli imoto.

I-4, Izindlela zokukhweza nokwehlisa ziyefana nalezo zama-bearings ajwayelekile.

● I-Hybird izala

1, Umzimba ogoqayo we-ceramic bearing yi-silicon nitride ceramic material.

2, Umzimba ogoqayo uvalekile, ususa i-overcurrent ekuthwaleni.

I-3, impahla ye-Ceramic inobunzima obuphezulu futhi ayizweli ekushintsheni kwezinga lokushisa, ngakho ingaba nesikhathi eside ekugcobeni.

I-4, Ukuze kuqinisekiswe umphumela wokufakelwa, lokhu kuthwala akufakwe isembozo sothuli.

Qaphela: Sithengisa kuphela izinjini, lapha vele sethule ama-motor bearings.

Isikhathi sokuthumela: Feb-20-2024