I-stepper motorisimiso sokusebenza

Ngokuvamile, i-rotor ye-motor iyizibuthe ezihlala njalo. Lapho i-current igeleza ku-stator winding, i-stator winding ikhiqiza insimu kazibuthe ye-vector. Le nkundla kazibuthe ishayela i-rotor ukuthi ijikeleze nge-engeli ukuze isiqondiso se-rotor yezinkundla kazibuthe siqondane naleyo ye-stator's field. Lapho i-vector magnetic field ye-stator izungeza nge-engeli.

I-stepper motoriwuhlobo lwemoto yokungenisa, umgomo wayo wokusebenza ukusetshenziswa kwesekethe ye-elekthronikhi, i-current eqondile ibe amandla okwabelana ngesikhathi, isilawuli sesikhathi se-multiphase samanje, nalesi samanje samandla kagesi we-stepper motor, i-stepper motor ingasebenza kahle, umshayeli ungowokuhlinzeka ngogesi we-stepper motor ngesikhathi sokwabelana, isilawuli sesikhathi se-multiphase.

Ukufaka ngakunye i-pulse kagesi, injini izungeza i-engeli phambili isinyathelo esisodwa. Ukukhipha kwayo i-angular displacement ilingana nenani le-pulses input, isivinini silingana nemvamisa ye-pulse. Shintsha ukuhleleka kokuqina kokuqina, injini izohlehla. Ngakho-ke ungakwazi ukulawula inani lama-pulses, imvamisa kanye nokuhleleka kokunika amandla isigaba ngasinye se-motor winding ukuze ulawule ukujikeleza kwe-stepper motor.

Ukunemba kwe-general stepper motor kungu-3-5% we-engeli yokunyathela, futhi ayiqoqi.

I-torque ye-stepper motor izokwehla njengoba ijubane likhuphuka. Njengoba i-stepper motor ijikeleza, i-inductance yesigaba ngasinye se-motor winding izokwakha amandla kagesi ahlehlayo; uma i-frequency iphezulu, amandla kagesi ahlehlayo aphezulu. Ngaphansi kwesenzo sayo, i-motor ene-frequency (noma isivinini) iyanda futhi isigaba samanje siyancipha, okuholela ekunciphiseni kwe-torque.

I-Stepper motor ingasebenza ngokujwayelekile ngesivinini esiphansi, kodwa uma iphakeme kunejubane elithile ngeke iqale, futhi ihambisane nokushaya ikhwela.

I-Stepper motor inepharamitha yobuchwepheshe: imvamisa yokuqalisa i-no-load, okungukuthi, i-stepper motor esimweni sokungalayishwa kwe-pulse frequency ingaqalwa ngokujwayelekile, uma imvamisa ye-pulse iphezulu kunevelu, i-motor ayikwazi ukuqala ngokujwayelekile, ingenzeka ngaphandle kwesinyathelo noma ivimbe.

Endabeni yomthwalo, imvamisa yokuqala kufanele ibe ngaphansi. Uma i-motor izothola ukujikeleza kwesivinini esikhulu, imvamisa ye-pulse kufanele ibe nenqubo yokusheshisa, okungukuthi, imvamisa yokuqala iphansi, bese ikhuphukela ku-frequency ephezulu oyifunayo (isivinini se-motor kusukela ngesivinini esiphansi kuya ngesivinini esikhulu) ngokusheshisa okuthile.

Kunganiama-stepper motorszidinga ukulawulwa ngokunciphisa isivinini

Isivinini se-stepper motor sincike kubuningi be-pulse, inani lamazinyo e-rotor kanye nenani lokushaywa. Ijubane layo elingu-angular lilingana nemvamisa yokushaya kwenhliziyo futhi livumelaniswa ngesikhathi neshayela. Ngakho-ke, uma inani lamazinyo e-rotor kanye nenani lama-beats agijimayo liqinisekile, isivinini esifunayo singatholakala ngokulawula imvamisa ye-pulse. Njengoba i-stepper motor iqalwa ngosizo lwe-torque yayo ehambisanayo, imvamisa yokuqala ayiphezulu ukuze ungalahlekelwa isinyathelo. Ikakhulukazi njengoba amandla ekhula, ububanzi be-rotor buyanda, i-inertia iyanda, futhi imvamisa yokuqala kanye nemvamisa yokugijima ephezulu ingase ihluke izikhathi eziyishumi.

Izici zokuqala zemvamisa ye-stepper motor ukuze i-stepper motor iqale ingakwazi ukufinyelela ngqo imvamisa yokusebenza, kodwa ibe nenqubo yokuqalisa, okungukuthi, isuka ngesivinini esiphansi kancane kancane ikhuphuke ifinyelele isivinini sokusebenza. Misa lapho i-frequency yokusebenza ingakwazi ukwehla ngokushesha iye ku-zero, kodwa ukuze ube nesivinini sokunciphisa isivinini esihamba kancane sibe yiziro.

Ngakho-ke, ukusebenza kwe-stepper motor ngokuvamile kufanele kudlule ukusheshisa, isivinini esifanayo, ukwehla kwezinyathelo ezintathu, inqubo yokusheshisa neyokunciphisa ibe mfushane ngangokunokwenzeka, isikhathi sesivinini esingaguquki eside ngangokunokwenzeka. Ikakhulukazi emsebenzini odinga impendulo esheshayo, isikhathi esidingekayo ukugijima kusukela ekuqaleni kuze kube sekupheleni yisona esifushane kakhulu, okumele sidinge inqubo emfushane yokusheshisa nokunciphisa, kanye nesivinini esiphezulu kakhulu ngesivinini esingaguquki.

Ukusheshisa nokunciphisa i-algorithm ingenye yobuchwepheshe obubalulekile ekulawuleni ukunyakaza, futhi enye yezinto ezibalulekile zokufinyelela isivinini esiphezulu nokusebenza kahle okuphezulu. Ekulawulweni kwezimboni, ngakolunye uhlangothi, inqubo yokucubungula iyadingeka ukuthi ibe bushelelezi futhi izinzile, ibe nomthelela omncane wokuguquguquka; ngakolunye uhlangothi, kudinga isikhathi sokuphendula esisheshayo nokusabela okusheshayo. Esimweni sokuqinisekisa ukunemba kokulawula ukuze kuthuthukiswe ukusebenza kahle kokucubungula, ukufeza ukunyakaza kwemishini okubushelelezi futhi okuzinzile, ukucubungula kwezimboni zamanje kube ukuxazulula inkinga ebalulekile. I-acceleration and deceleration algorithms evame ukusetshenziswa ezinhlelweni zamanje zokulawula ukunyakaza ikakhulukazi ihlanganisa: ukusheshisa kwe-trapezoidal curve kanye nokwehla, ukusheshisa nokwehla kwejika lejika, ukusheshisa nokwehla kwejika elimise okuka-S, ukusheshisa kwejika le-parabolic kanye nokwehla, njll.

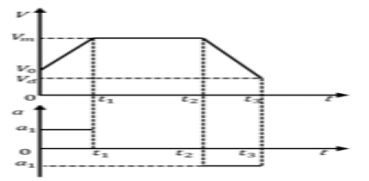

Ukusheshisa kwejika le-Trapezoidal kanye nokwehla

Incazelo: Ukusheshisa/ukwehlisa ijubane ngendlela yomugqa (ukusheshisa/ukwehla ukusuka esivinini sokuqala ukuya kusivinini esiqondiwe) ngesilinganiso esithile

Ifomula yokubala: v(t)=Vo+at

Izinzuzo kanye nokubi: Ijika le-Trapezoidal libonakala nge-algorithm elula, isikhathi esincane esidliwayo, impendulo esheshayo, ukusebenza kahle okuphezulu kanye nokuqaliswa okulula. Kodwa-ke, izigaba zokusheshisa nokunciphisa iyunifomu azihambisani nomthetho wokushintsha isivinini se-stepper motor, futhi iphuzu lokushintsha phakathi kwejubane eliguquguqukayo nesivinini somfaniswano alikwazi ukushelela. Ngakho-ke, le-algorithm isetshenziswa ikakhulukazi ezinhlelweni lapho izidingo zenqubo yokusheshisa nokunciphisa izinga zingekho phezulu.

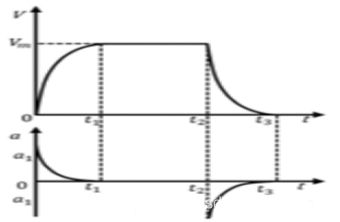

Ukusheshisa kwejika nokuncishiswa kwejika

Incazelo: Kusho ukusheshisa kanye nokwehla ngokusebenza komchazi.

Inkomba yokuhlola yokulawula ukusheshisa nokunciphisa:

I-1, Iphutha lokulandela umshini nesikhundla kufanele libe lincane ngangokunokwenzeka

2, Inqubo yokunyakaza komshini ibushelelezi, i-jitter incane, futhi impendulo iyashesha

3, ukusheshisa kanye ne-algorithm yokunciphisa izinga kufanele kube lula ngangokunokwenzeka, kube lula ukuyisebenzisa, futhi ingahlangabezana nezidingo zokulawula isikhathi sangempela

Uma ufuna ukuxhumana nokusebenzisana nathi, sicela ukhululeke ukuxhumana nathi.

Sisebenzelana eduze namakhasimende ethu, silalela izidingo zawo futhi senze ngokwezicelo zawo. Sikholelwa ukuthi ubambiswano lokuwina lusekelwe kwikhwalithi yomkhiqizo kanye nesevisi yamakhasimende.

I-Changzhou Vic-tech Motor Technology Co., Ltd. iyinhlangano yocwaningo nokukhiqiza yochwepheshe egxile ocwaningweni lwezimoto nasekuthuthukisweni, izixazululo eziphelele zokusetshenziswa kwezimoto, nokucutshungulwa nokukhiqizwa kwemikhiqizo yezimoto. Ltd. ibikhethekile ekukhiqizeni amamotho amancane nezinye izinsimbi kusukela ngo-2011. Imikhiqizo yethu eyinhloko: amamotho amancane anyathelayo, amagiya, amamotho ahlosiwe, ama-thruster angaphansi kwamanzi kanye nezishayeli nezilawuli.

Ithimba lethu lineminyaka engaphezu kwengu-20 yesipiliyoni ekuklameni, ekuthuthukiseni nasekukhiqizeni ama-micro-motor, futhi lingathuthukisa imikhiqizo futhi lisize amakhasimende aklame ngokwezidingo ezikhethekile! Njengamanje, sidayisela amakhasimende amakhulu emazweni ase-Asia, eNyakatho Melika naseYurophu, njenge-USA, UK, Korea, Germany, Canada, Spain, njll. Ifilosofi yethu yebhizinisi "yobuqotho nokuthembeka, egxile eqophelweni", "ikhasimende kuqala" izindinganiso zenani zikhuthaza ukuqamba okusha okugxile ekusebenzeni, ukubambisana, umoya osebenzayo webhizinisi, ukusungula umgomo wethu wokugcina "umgomo wethu wokugcina" ukwakha amakhasimende ethu.

Isikhathi sokuthumela: Jun-27-2023